Gallium nitride is the most important 'new' charging innovation you'll never see

You don't need to know about a FET or what a bandgap is, but the company that makes the gadgets you buy does. And it's all on the verge of a big change for the better — in ways we will see, like safer, more efficient, and smaller high-power chargers — because of a chemical compound called Gallium nitride.

Back on October 25, Anker held an event to show off some of its latest innovations, including a new USB-C Power Delivery wall charger that uses GaN semiconductors. Normally, nobody would care about the launch of wall wart that charges your devices, but this time things are different. Anker's new PowerPort Atom PD1 charger offers 27 watts of output power and is the size of the little charging block that came in the box with your last phone. To put it another way that's a little more exciting, it puts out enough power to effectively fast charge a MacBook Pro and is about one-third of the size. It's also cooler to the touch and will use less power because it's more efficient.

Anker isn't the only company out of China to build a USB Power Deliver charger using GaN FETs (a FET is a Field-effect transistor and is used to control the flow and behavior of electricity). RAVPower has a 45-watt model in the works and industry experts say all the names you've already heard of will soon be offering a high-output, cool-running, and low profile high output USB-C Power Delivery chargers using the technology. Not because Gallium nitride is something new, but because it can now be profitable.

GaN is the optical layer on the LED that reads CDs, DVDs, and Blu-Ray discs so you're already using it.

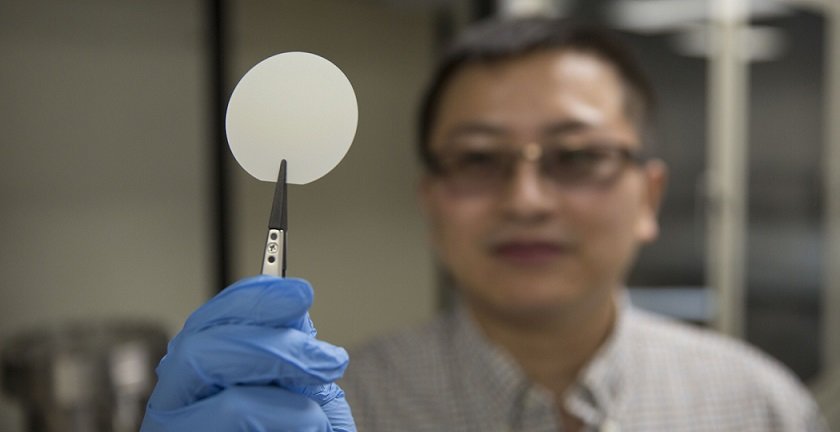

Gallium nitride is already used in products you own, but for an entirely different purpose. GaN crystals have been used on a sapphire base to produce full-spectrum LEDs for quite a while, and if you have any RGB or "Daylight" LED lamps, they are probably using Gallium nitride. Other specialty uses like high-end Class D audio amplifiers and microwave telecom equipment also use GaN, and everything that uses it does so for the same three reasons. Compared to a traditional silicon transistor, Gallium nitride runs cooler, is more power efficient, and a lot smaller — which is exactly what you see when you look at Anker's new tiny 27 watt USB-PD charging block. GaN has always been a superior bandgap semiconductor compared to silicon, but it's also been much more expensive to reliably produce.

It's always been more cost-efficient to build a GaN device than a traditional silicon device because of its final footprint. Simply put, you can fit a lot more GaN FETs on a wafer than you can MOSFETs, which use a silicon base. The problem was the cost of the wafers themselves. A Gallium nitride wafer is still more expensive than a silicon wafer of the same size, but production techniques have been refined (turns out nitrogen made a mess of things) and the gap is narrow enough to make it an attractive option for companies that produce the transistors. This has caused a huge uptick in the market, with 17% growth per year expected between 2019 and 2024.

How this affects us

I'll assume that almost everyone reading this doesn't care if the tiny parts inside their gadgets use silicon or Gallium nitride or pixie dust, as long as they work. But I also know that carrying a tiny Anker charger instead of a big heavy brick charger for my laptop would make me happy. When I realize that this same charger will also work for my phone, my tablet, my Nintendo Switch, and even my wireless charging case for my Bluetooth earbuds, I'm even happier. We want our tech to become more complicated — do more things in cooler ways — while becoming less complicated at the same time.

Safety shouldn't be ignored, either. A GaN device uses less power to operate (you need to supply an electronic switch with its own power to make it able to switch input and output power) and switches a lot faster. This makes it run cooler so less electricity is lost as heat and it's more efficient, but also safer. It's been well over two years since the Samsung Galaxy Note 7, but the learning experience it gave many of us will always live on: our portable electronic devices can be dangerous in extreme circumstances.

Get the latest news from Android Central, your trusted companion in the world of Android

Moore's law always meets Murphy's Law if you give things enough time.

Each iteration of all the various fast charging techniques brings us closer and closer to those extremes and we haven't even come close to the end. Several years ago I got to witness a demonstration of a microwave oven heating a frozen pizza while being powered using a wireless charging plate. I watched behind a plexiglass blast shield because even though you can power a 1,500-watt device using induction, that doesn't mean it can't go wrong.

While we will never need to use 1,500 watts to power a phone or even a laptop (maybe the Nintendo Switch 2?) 9 watts can be dangerous when everything isn't done correctly. As we call for smaller and more convenient things, manufacturers have to edge closer to the extreme to deliver. Small, unseen things like a change in the semiconductor base which allows for more efficient and safer things gives those manufacturers more room. Not everything that makes the next generation great is something we can see.

Jerry is an amateur woodworker and struggling shade tree mechanic. There's nothing he can't take apart, but many things he can't reassemble. You'll find him writing and speaking his loud opinion on Android Central and occasionally on Threads.