Headquartered in Corning, New York and founded in 1851 – yes, the company is over 160 years old – Corning Incorporated is one of the world's leading innovators in materials science. The Fortune 500 company operates in diverse market segments like Optical Communications, Display Technology, Specialty Materials, Life Sciences, and Environmental Technologies with expertise in specialty glass, ceramics, and optical physics.

However, the product that has brought them instant recognition in technology space has been Gorilla Glass, the damage-resistant cover glass used in thousands of mobile devices.

I visited the Sullivan Park research facility in Corning, NY earlier this year to find out more about glass strength, damage resistance, and of course, Gorilla Glass, and how it fares against other chemically strengthened glasses in the market. Asahi Glass Co.'s Dragontrail and Schott AG Xensation are the other players in the market that offer strengthened glass for smart devices.

Why Gorilla Glass?

As leaders in 'glass', Corning saw that the consumer electronics industry required a tough and durable cover glass driven by the use of touch. Of course, damage resistance and design capabilities are key product requirements. Such a product would help OEMs differentiate and enhance user experience offering thin and light displays with optical clarity offering flexibility in device design.

In less than ten years, Corning Gorilla Glass is now an industry standard with significant brand awareness. Many smartphone buyers look up the specifications sheet to spot 'Gorilla Glass' making it an important consideration when making a purchase decision. Gorilla has been designed into more than 1,800 models, and an excess of 4.5 billion devices have been released in the market with Gorilla Glass!

According to the company, over 40 OEMs have designed models with Gorilla Glass and many have used the Gorilla Glass brand as a key selling tool. These include major device brands like HTC, LG, Acer, HP, Asus, Dell, Samsung, Lenovo, Microsoft, and Motorola as well as Chinese giants like Meizu, ZTE, and Huawei, and Indian players like Micromax.

Recently, Ford Motor Company announced that it will be using the material for the windshield, the rear window, and bulkhead on its Ford GT supercar.

Get the latest news from Android Central, your trusted companion in the world of Android

What is damage resistance?

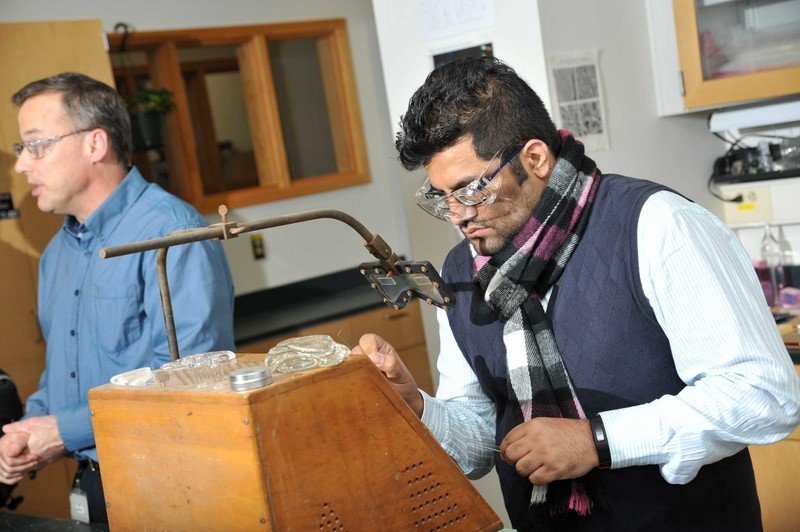

During my visit to the Corning Labs (Corning has many other labs, including two research facilities - Corning Technology Center in Shizuoka, Japan and Corning Research Center Taiwan in Hsinchu, Taiwan) in freezing February this year, I spent some time with the researchers who work on materials science and Gorilla Glass.

Of course, the first step was to understand 'damage resistance' – the ability for a material to limit strength reduction due to flaws evaluated by measuring the retained strength of a material after damage has been introduced.

To understand damage resistance, we did tests on different types of Gorilla Glass compositions and traditional soda lime glass. Soda lime glass is similar in composition to the glass found in most windows today.

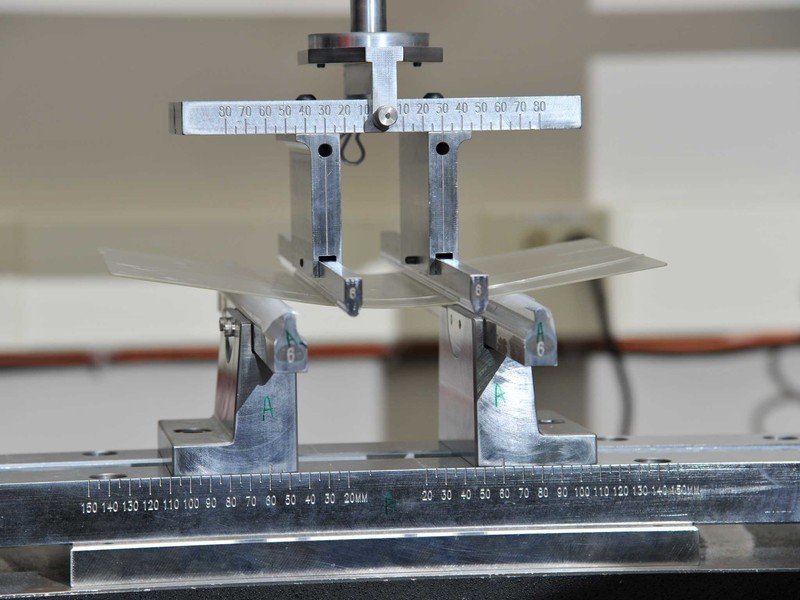

Abraded Ring-on-Ring (ARoR) test involved abrading the surface of the glass with silicon carbide particles to simulate in-field impact events, followed by a standard Ring-on-Ring (RoR) test to measure retained strength. Scratch Ring-on-Ring (SRoR) involved scratching a glass surface followed by a standard RoR test to measure retained strength.

While the theoretical strength of glass is very high, its strength is greatly reduced when a defect or flaw is introduced. Glass almost always breaks from a surface flaw that is subjected to tensile stress (pulling apart/stretching).

How is Gorilla Glass made?

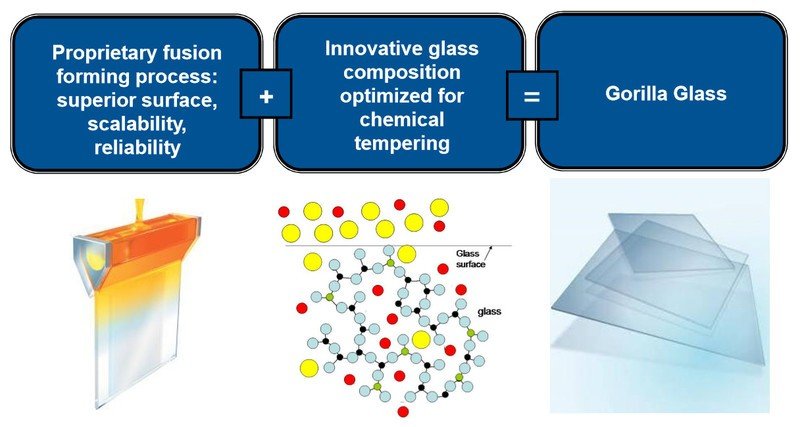

Corning's proprietary fusion manufacturing process produces a thin sheet cover glass with pristine surface quality, outstanding optical clarity, and inherent dimensional stability. According to the company,

The process begins when raw materials are blended into a glass composition, which is melted and conditioned. The molten glass is fed into a trough called an "isopipe," overfilling until the glass flows evenly over both sides. It then re-joins, or fuses, at the bottom, where it is drawn down to form a continuous sheet of flat glass that is so thin it is measured in microns. The glass is untouched by human hands or anything else that will introduce flaws into the surface.

The composition of Gorilla Glass enables a deep layer of chemical strengthening through an ion-exchange process where individual glass parts are cut from the 'mother sheet' and undergo an ion-exchange process.

Ion exchange is a chemical strengthening process where large ions are "stuffed" into the glass surface, creating a state of compression. Gorilla Glass is specially designed to maximize this behavior. The glass is placed in a hot bath of molten salt at a temperature of approximately 400 degrees Celcius. Smaller sodium ions leave the glass, and larger potassium ions from the salt bath replace them. These large ions take up more room and are pressed together when the glass cools, producing a layer of compressive stress on the surface of the glass. Gorilla Glass' composition enables the potassium ions to diffuse far into the surface, creating high compressive stress deep into the glass. This layer of compression creates the surface that is more resistant to damage.

Evolution of Corning Gorilla Glass

Corning experimented with chemically strengthened glass in 1960, as part of a 'Project Muscle' initiative. Marketed as Chemcor, the 'muscled glass' was used until the early 1990s in commercial and industrial applications, notably in 1968 Dodge Dart and Plymouth Barracuda racing cars, where minimizing the vehicle's weight was essential.

In 2005, investigating whether the type of tough glass could be made thin enough for use in consumer electronics, Corning used this glass technology to invent a brand new glass composition, Gorilla Glass.

Corning Gorilla Glass was commercialized in 2007, and as I discovered myself in the lab tests, it outperforms plastic covers for scratch resistance as well as strengthened soda lime when damaged.

It was followed by Gorilla Glass 2 in 2012 that offered increased damage resistance or thickness reduction. Compared to the original Gorilla Glass, Corning Gorilla Glass 2 provided over 25% increase in damage resistance. OEM customers could choose to use the improved performance in one of two ways - higher retained strength at same thickness or up to 20% reduced thickness with equivalent retained strength.

In 2013, Corning Gorilla Glass 3 with Native Damage Resistance arrived. Compared to Gorilla Glass 2, Gorilla Glass 3 with NDR offered improved scratch resistance, reduced scratch visibility, and improved retained strength after scratch.

Gorilla Glass 4

According to Square Trade Inc., "You are 10x more likely to break your phone than lose it or get it stolen." Broken mobile devices are a common problem, and overwhelmingly the top issue consumers want improved in their displays.

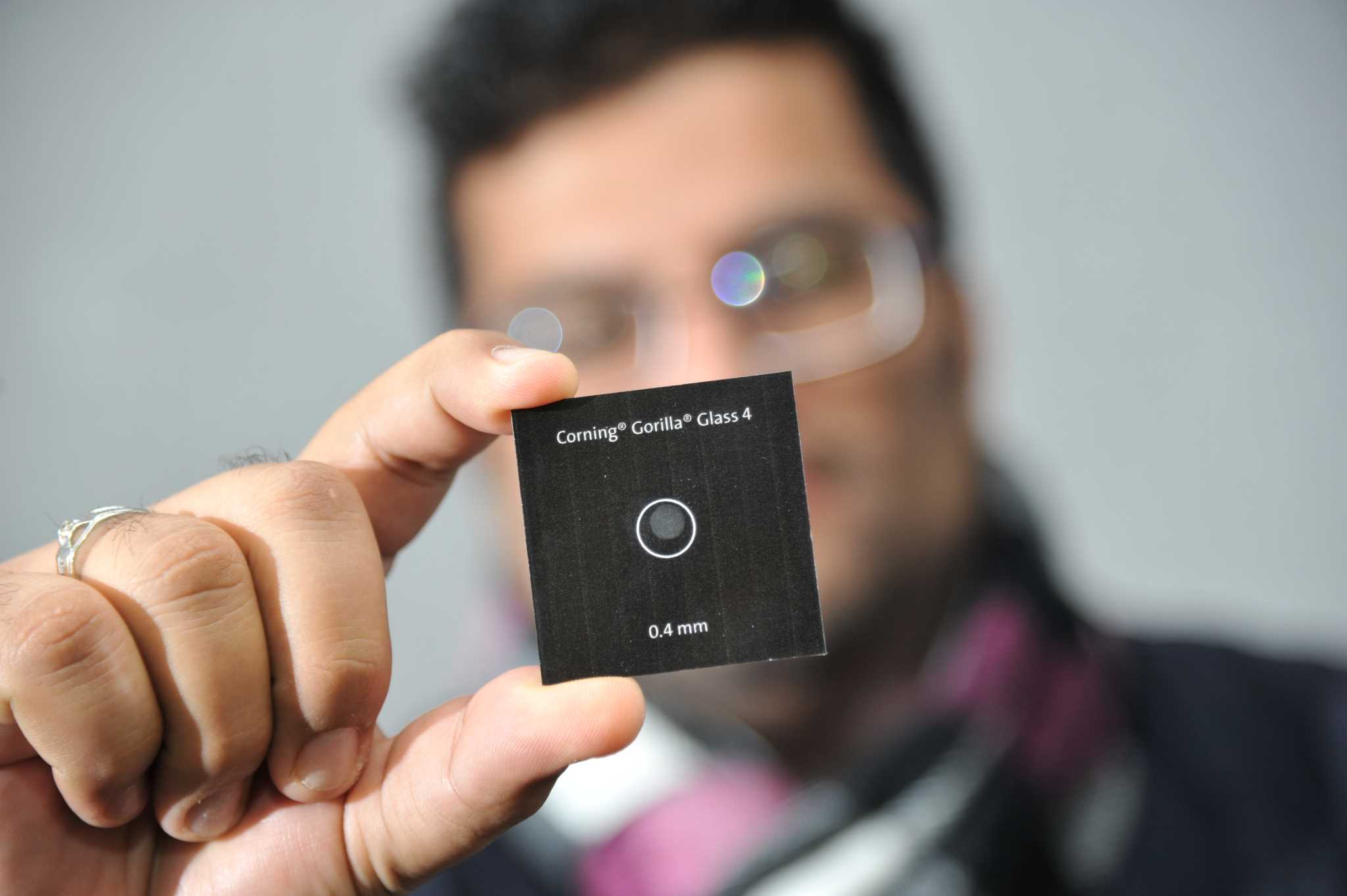

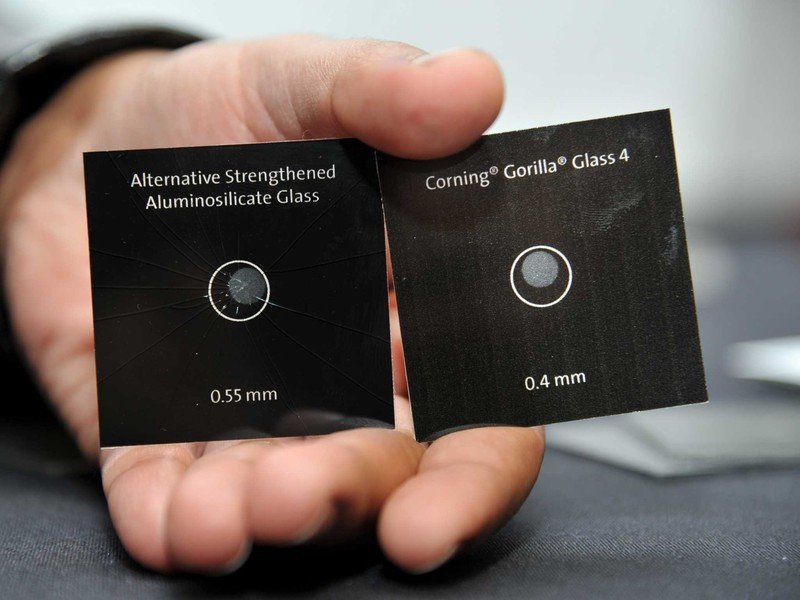

Gorilla Glass 4 was formulated to address breakage and delivers the highest damage resistance to date, and has the capability to significantly improve device drop performance. The company claims that Gorilla Glass 4 withstood such drops up to two times better than competing glass designs. When it comes to drop performance on rough surfaces, while Gorilla Glass 4 survives up to 80% of the time, soda lime glass breaks nearly 100% of the time.

Advantages of Gorilla Glass

Of course, the primary advantage of Corning Gorilla Glass is damage resistance. Gorilla Glass is chemically strengthened through an ion-exchange process that creates a deep compression layer on the surface of the glass substrate. This layer acts as a sort of armor to reduce the introduction of flaws.

Also, the process produces glass with exceptionally clean, smooth, flat surfaces and outstanding optical clarity making it a great cover sheet for touch screens. It's tough enough to handle the surface pressures intrinsic to these devices, and exceptionally thin to enable more sensitive and accurate responses.

Gorilla Glass can be produced in thicknesses ranging from 0.4 mm to 2 mm, and even at 0.4 mm the company claims that the Gorilla Glass retains a performance advantage over many other cover materials.